| Availability: | |

|---|---|

| Quantity: | |

SPS20-1000S

SP

8543709990

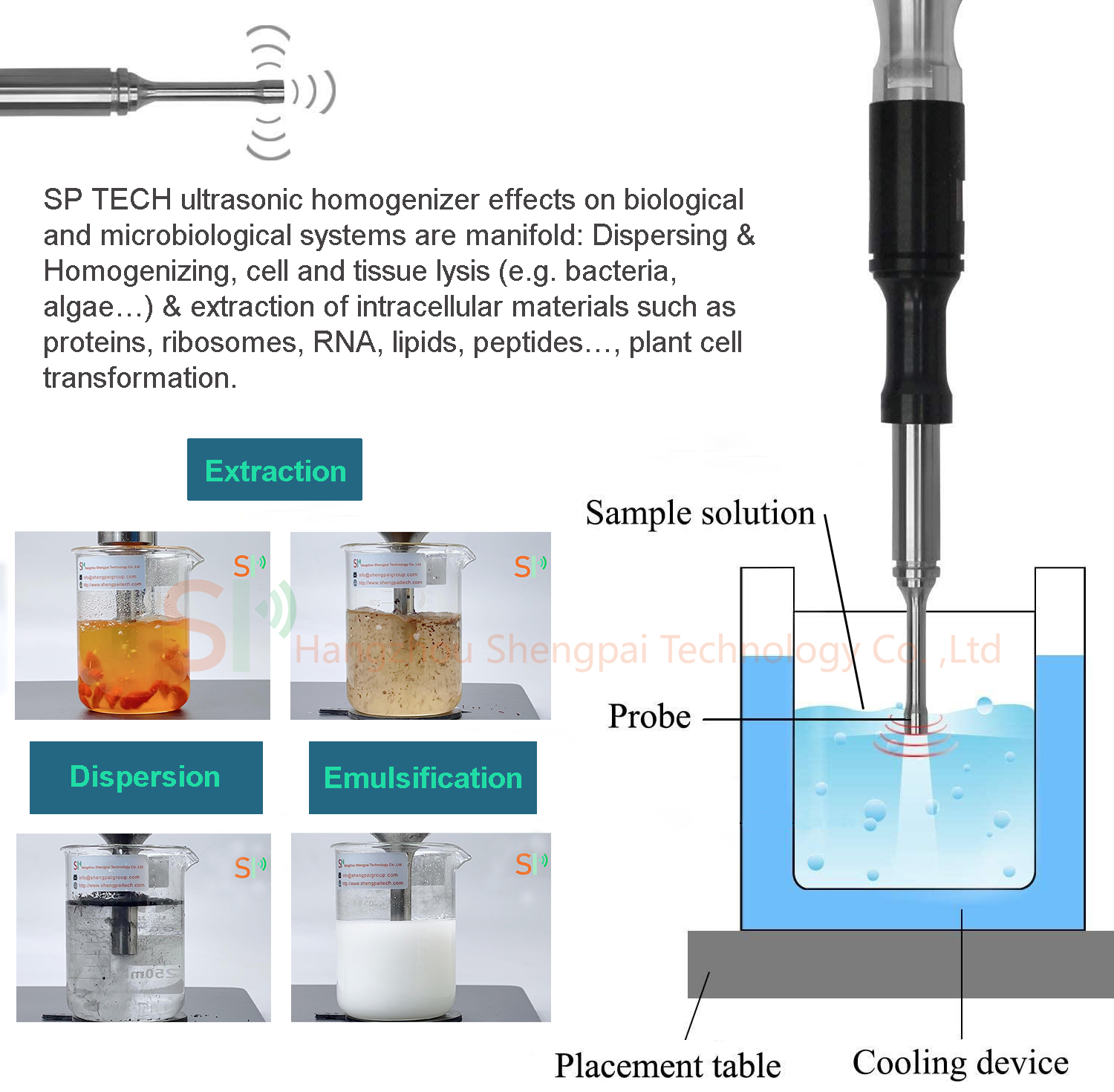

When high-power, low-frequency ultrasonic waves are coupled to a slurry composed of plant materials in a solvent, ultrasonic extraction can be achieved. High-power ultrasonic waves are coupled into the slurry through a probe-type ultrasonic processor. High-energy ultrasonic waves propagate in the liquid, generating high-pressure/low-pressure alternating cycles, resulting in acoustic cavitation. Acoustic cavitation or ultrasonic cavitation can locally cause extreme temperatures, pressures, heating/cooling rates, pressure differences, and high shear forces in the medium. When cavitation bubbles implode on the surface of solids (such as particles, plant cells, tissues, etc.), micro-jets and joint collisions produce effects such as surface peeling, erosion, particle rupture, acoustic perforation (perforation of cell walls and cell membranes), and cell rupture. . In addition, the implosion of cavitation bubbles in the liquid medium will produce macro-turbulence and micro-mixing. Ultrasonic irradiation is an effective method to enhance the mass transfer process, because the effect of ultrasound can cause cavitation and its related mechanisms, such as the microscopic movement of liquid jets, compression and decompression in materials, and subsequent destruction of cell walls, as well as high heating and Cooling rate. Probe-type ultrasonic generators can generate very high amplitudes, which are necessary to generate impact cavitation. SP-TECH produces high-performance ultrasonic extractors that can easily generate 100µm amplitude in continuous operation.

When high-power, low-frequency ultrasonic waves are coupled to a slurry composed of plant materials in a solvent, ultrasonic extraction can be achieved. High-power ultrasonic waves are coupled into the slurry through a probe-type ultrasonic processor. High-energy ultrasonic waves propagate in the liquid, generating high-pressure/low-pressure alternating cycles, resulting in acoustic cavitation. Acoustic cavitation or ultrasonic cavitation can locally cause extreme temperatures, pressures, heating/cooling rates, pressure differences, and high shear forces in the medium. When cavitation bubbles implode on the surface of solids (such as particles, plant cells, tissues, etc.), micro-jets and joint collisions produce effects such as surface peeling, erosion, particle rupture, acoustic perforation (perforation of cell walls and cell membranes), and cell rupture. . In addition, the implosion of cavitation bubbles in the liquid medium will produce macro-turbulence and micro-mixing. Ultrasonic irradiation is an effective method to enhance the mass transfer process, because the effect of ultrasound can cause cavitation and its related mechanisms, such as the microscopic movement of liquid jets, compression and decompression in materials, and subsequent destruction of cell walls, as well as high heating and Cooling rate. Probe-type ultrasonic generators can generate very high amplitudes, which are necessary to generate impact cavitation. SP-TECH produces high-performance ultrasonic extractors that can easily generate 100µm amplitude in continuous operation. Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. Core parts with Titanium alloy materials

2. Ultrasonic probe with different size and type for selection

3. Matching with digital generator, auto-tuning, auto search frequency

4. With automatic alarm protection, easy to operate

5. Power adjustable from 1% to 99%

6. Amplitude stability and high, long working hours, more efficiency

7. Provide consulting services and custom reactor designs

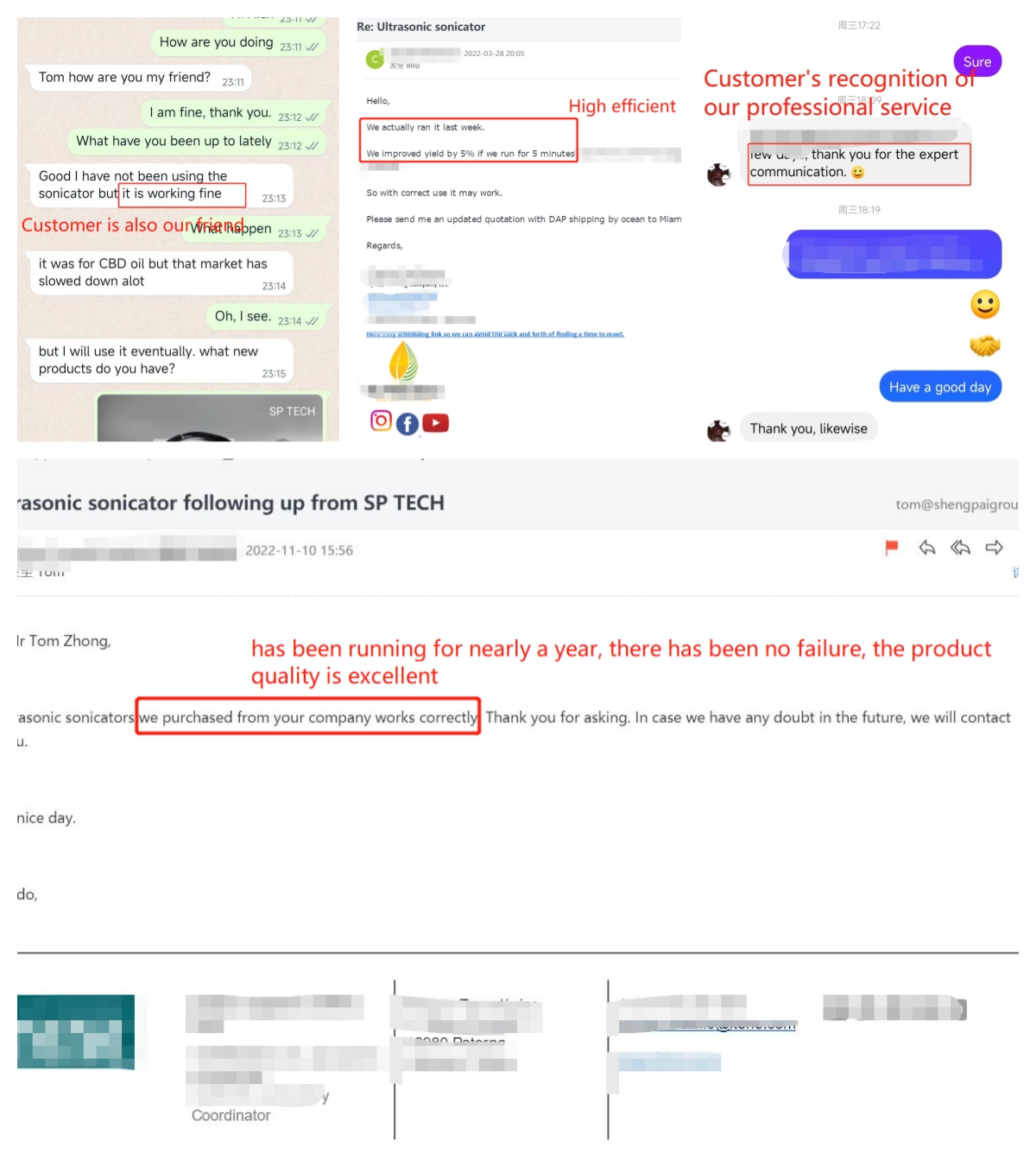

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

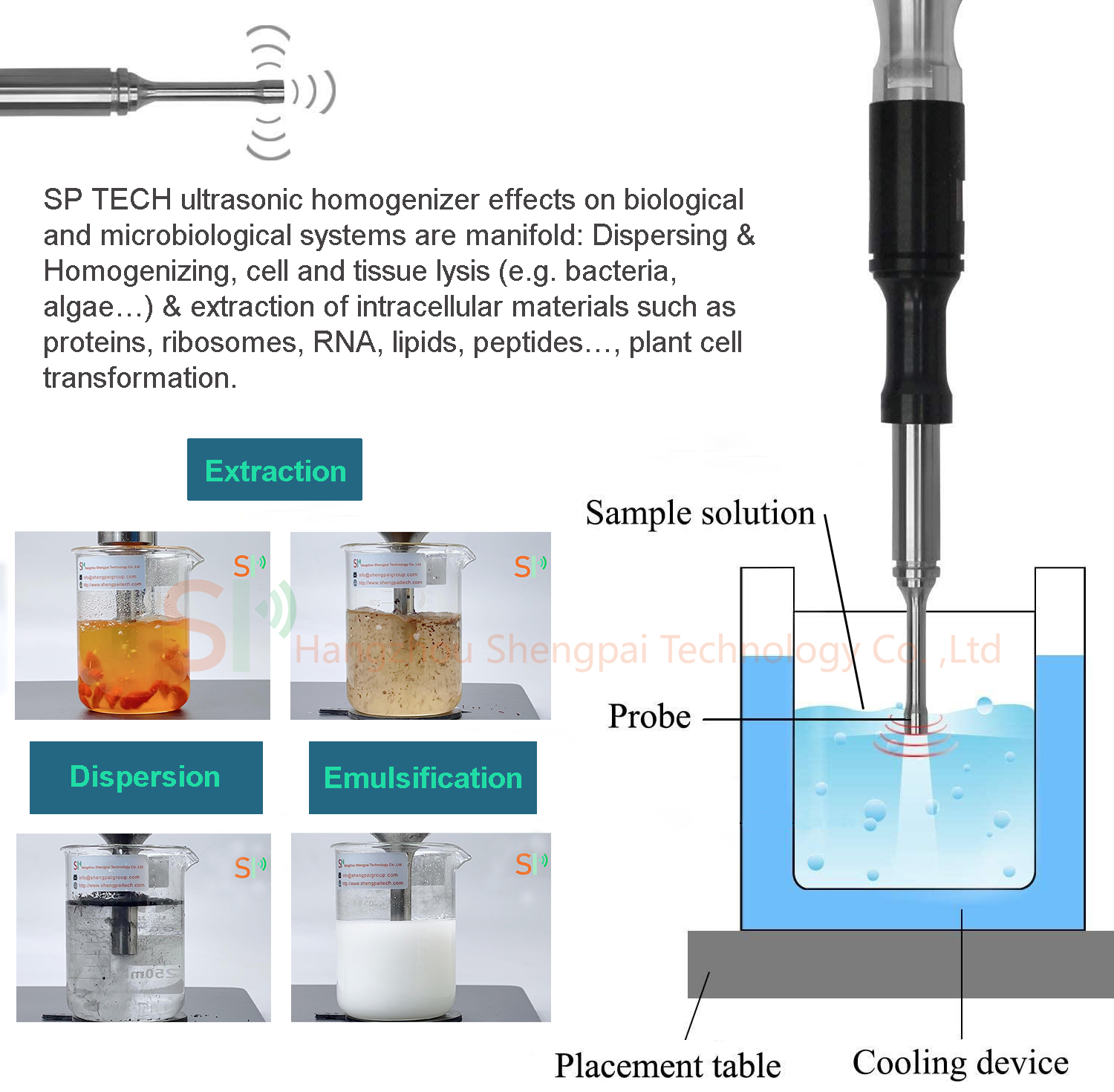

When high-power, low-frequency ultrasonic waves are coupled to a slurry composed of plant materials in a solvent, ultrasonic extraction can be achieved. High-power ultrasonic waves are coupled into the slurry through a probe-type ultrasonic processor. High-energy ultrasonic waves propagate in the liquid, generating high-pressure/low-pressure alternating cycles, resulting in acoustic cavitation. Acoustic cavitation or ultrasonic cavitation can locally cause extreme temperatures, pressures, heating/cooling rates, pressure differences, and high shear forces in the medium. When cavitation bubbles implode on the surface of solids (such as particles, plant cells, tissues, etc.), micro-jets and joint collisions produce effects such as surface peeling, erosion, particle rupture, acoustic perforation (perforation of cell walls and cell membranes), and cell rupture. . In addition, the implosion of cavitation bubbles in the liquid medium will produce macro-turbulence and micro-mixing. Ultrasonic irradiation is an effective method to enhance the mass transfer process, because the effect of ultrasound can cause cavitation and its related mechanisms, such as the microscopic movement of liquid jets, compression and decompression in materials, and subsequent destruction of cell walls, as well as high heating and Cooling rate. Probe-type ultrasonic generators can generate very high amplitudes, which are necessary to generate impact cavitation. SP-TECH produces high-performance ultrasonic extractors that can easily generate 100µm amplitude in continuous operation.

When high-power, low-frequency ultrasonic waves are coupled to a slurry composed of plant materials in a solvent, ultrasonic extraction can be achieved. High-power ultrasonic waves are coupled into the slurry through a probe-type ultrasonic processor. High-energy ultrasonic waves propagate in the liquid, generating high-pressure/low-pressure alternating cycles, resulting in acoustic cavitation. Acoustic cavitation or ultrasonic cavitation can locally cause extreme temperatures, pressures, heating/cooling rates, pressure differences, and high shear forces in the medium. When cavitation bubbles implode on the surface of solids (such as particles, plant cells, tissues, etc.), micro-jets and joint collisions produce effects such as surface peeling, erosion, particle rupture, acoustic perforation (perforation of cell walls and cell membranes), and cell rupture. . In addition, the implosion of cavitation bubbles in the liquid medium will produce macro-turbulence and micro-mixing. Ultrasonic irradiation is an effective method to enhance the mass transfer process, because the effect of ultrasound can cause cavitation and its related mechanisms, such as the microscopic movement of liquid jets, compression and decompression in materials, and subsequent destruction of cell walls, as well as high heating and Cooling rate. Probe-type ultrasonic generators can generate very high amplitudes, which are necessary to generate impact cavitation. SP-TECH produces high-performance ultrasonic extractors that can easily generate 100µm amplitude in continuous operation. Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. Core parts with Titanium alloy materials

2. Ultrasonic probe with different size and type for selection

3. Matching with digital generator, auto-tuning, auto search frequency

4. With automatic alarm protection, easy to operate

5. Power adjustable from 1% to 99%

6. Amplitude stability and high, long working hours, more efficiency

7. Provide consulting services and custom reactor designs

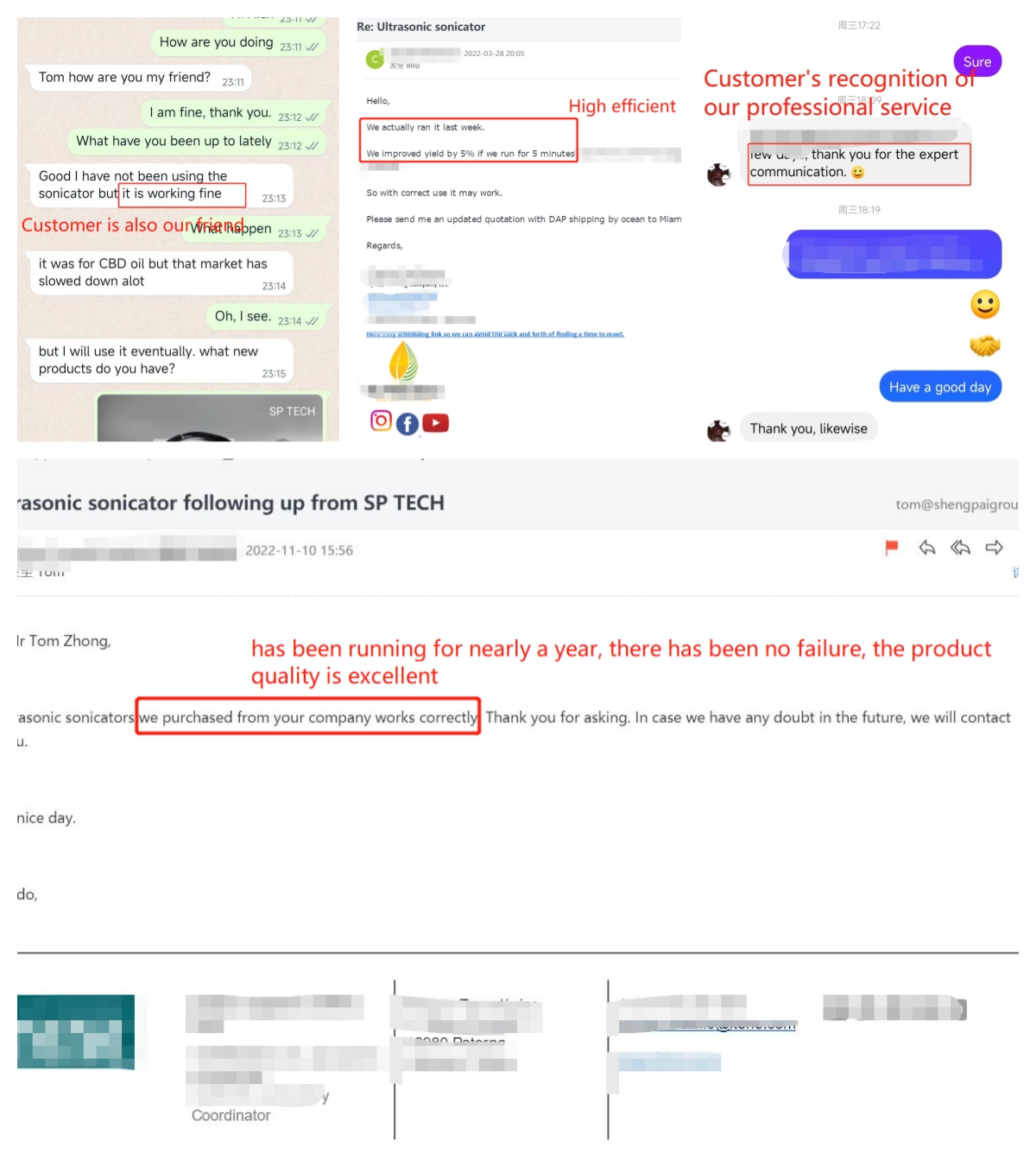

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com/ Lee@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15268128194

NEWSLETTER

Signup to be the first to know about discounts and new product releases.