| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000Z

SP

8543709990

Product Overview:

Ultrasonic Emulsification for Nanoemulsion and Microemulsion Production

Ultrasonic emulsification is a highly effective method for producing stable emulsions, including nanoemulsions and microemulsions, by dispersing two or more immiscible liquids using high-power ultrasound. In this process, ultrasonic cavitation generates intense shear forces and shock waves that break down the dispersed phase into ultra-fine droplets within the continuous phase. These droplet sizes can be reduced to below 1 micron, resulting in uniform and stable emulsions ideal for pharmaceutical, cosmetic, food, and chemical applications.

During ultrasonication, acoustic cavitation produces rapidly collapsing vacuum bubbles in the liquid, which creates localized hot spots with temperatures up to 5,000 K and pressures up to 1,000 atm. These extreme conditions generate microjets and strong shear forces, enhancing the mixing process and leading to smaller droplet sizes, improved emulsion stability, and a significantly increased interfacial surface area between components.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic treatment of chemical extraction, biodiesel production, organic synthesis, treatment of microorganisms, degradation of toxic organic pollutants, chemical reaction rate and yield, catalytic efficiency of catalysts, biodegradation treatment, ultrasonic anti-scaling, biological cell comminution, dispersion and coagulation A local small environment that is very beneficial to the reaction process can greatly increase the reaction rate and reduce the reaction conditions.

1. The emulsification quality is high. The average droplet size of the formed emulsion is small, which can reach 0.2~2um. The droplet size distribution range is narrow, up to 0.1~10um. The concentration is high, the concentration of pure emulsion can reach 30%, adding emulsifier can reach 70%.

2. The emulsification is stable, you can produce stable emulsions without or with less emulsifiers, and some can be stable for several months or even more than half a year, with low energy consumption, high production efficiency and low cost.

3. The type of emulsion can be controlled. Under certain sound field conditions, both oil-in-water and water-in-oil emulsions can be prepared. However, it is impossible to achieve mechanical emulsification. Only the properties of emulsifiers can control the type of emulsion. For example, when toluene is emulsified in water, one type of emulsion can be formed under low sound intensity conditions, and another type of emulsion can be formed under high sound intensity conditions.

4. Low power required to produce emulsion.

5. The type of emulsion can be controlled. Using ultrasonic emulsification, under certain sound field conditions, both O/W (oil-in-water) and W/O (water-in-oil) emulsions can be prepared; however, mechanical emulsification is impossible, and only the properties of the emulsifier can control the emulsion type.

1. Core parts with Titanium alloy materials

2. Ultrasonic probe with different size and type for selection

3. Matching with digital generator, auto-tuning, auto search frequency

4. With automatic alarm protection, easy to operate

5. Power adjustable from 1% to 99%

6. Amplitude stability and high, long working hours, more efficiency

7. Provide consulting services and custom reactor designs

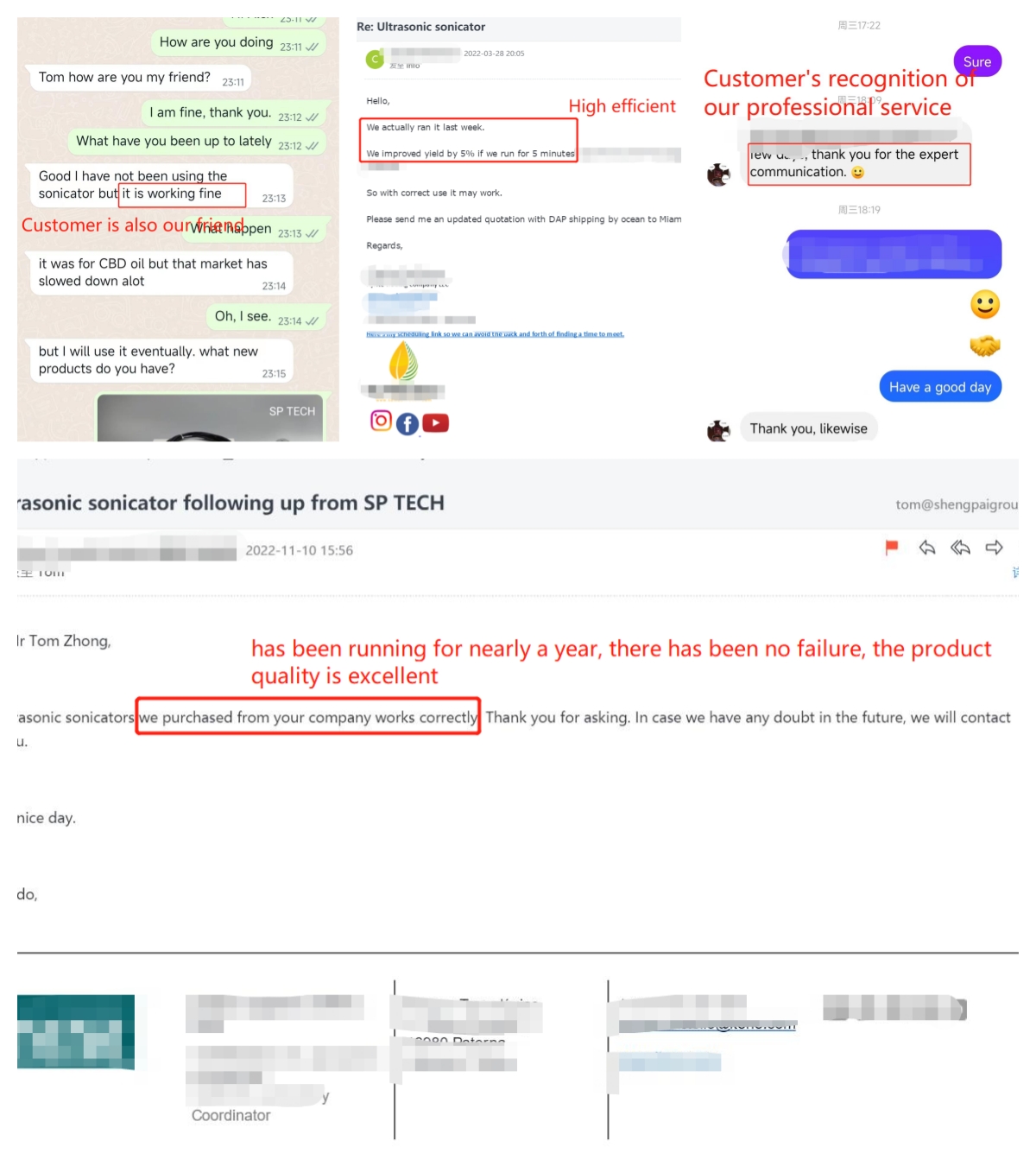

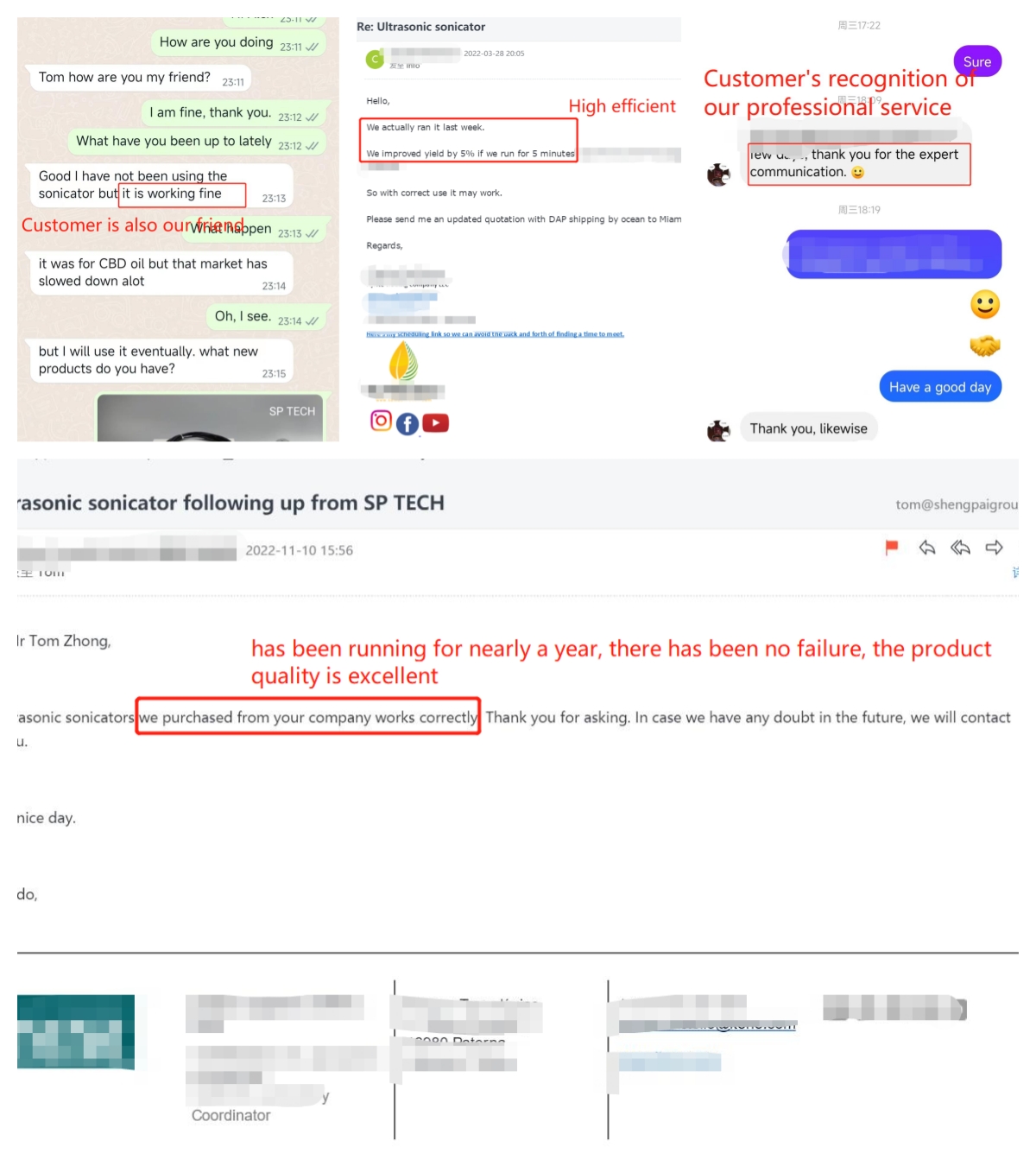

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Product Overview:

Ultrasonic Emulsification for Nanoemulsion and Microemulsion Production

Ultrasonic emulsification is a highly effective method for producing stable emulsions, including nanoemulsions and microemulsions, by dispersing two or more immiscible liquids using high-power ultrasound. In this process, ultrasonic cavitation generates intense shear forces and shock waves that break down the dispersed phase into ultra-fine droplets within the continuous phase. These droplet sizes can be reduced to below 1 micron, resulting in uniform and stable emulsions ideal for pharmaceutical, cosmetic, food, and chemical applications.

During ultrasonication, acoustic cavitation produces rapidly collapsing vacuum bubbles in the liquid, which creates localized hot spots with temperatures up to 5,000 K and pressures up to 1,000 atm. These extreme conditions generate microjets and strong shear forces, enhancing the mixing process and leading to smaller droplet sizes, improved emulsion stability, and a significantly increased interfacial surface area between components.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic treatment of chemical extraction, biodiesel production, organic synthesis, treatment of microorganisms, degradation of toxic organic pollutants, chemical reaction rate and yield, catalytic efficiency of catalysts, biodegradation treatment, ultrasonic anti-scaling, biological cell comminution, dispersion and coagulation A local small environment that is very beneficial to the reaction process can greatly increase the reaction rate and reduce the reaction conditions.

1. The emulsification quality is high. The average droplet size of the formed emulsion is small, which can reach 0.2~2um. The droplet size distribution range is narrow, up to 0.1~10um. The concentration is high, the concentration of pure emulsion can reach 30%, adding emulsifier can reach 70%.

2. The emulsification is stable, you can produce stable emulsions without or with less emulsifiers, and some can be stable for several months or even more than half a year, with low energy consumption, high production efficiency and low cost.

3. The type of emulsion can be controlled. Under certain sound field conditions, both oil-in-water and water-in-oil emulsions can be prepared. However, it is impossible to achieve mechanical emulsification. Only the properties of emulsifiers can control the type of emulsion. For example, when toluene is emulsified in water, one type of emulsion can be formed under low sound intensity conditions, and another type of emulsion can be formed under high sound intensity conditions.

4. Low power required to produce emulsion.

5. The type of emulsion can be controlled. Using ultrasonic emulsification, under certain sound field conditions, both O/W (oil-in-water) and W/O (water-in-oil) emulsions can be prepared; however, mechanical emulsification is impossible, and only the properties of the emulsifier can control the emulsion type.

1. Core parts with Titanium alloy materials

2. Ultrasonic probe with different size and type for selection

3. Matching with digital generator, auto-tuning, auto search frequency

4. With automatic alarm protection, easy to operate

5. Power adjustable from 1% to 99%

6. Amplitude stability and high, long working hours, more efficiency

7. Provide consulting services and custom reactor designs

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com/ Lee@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15268128194

NEWSLETTER

Signup to be the first to know about discounts and new product releases.